VEHICLE

Vehicle on display at the museum. Our pride and joy!

These vehicles are currently on display at the museum. while they do look great in picture form, they look incredible when you see them in person! At the museum, we want everyone to see these vehicles up close and personal so that they can see just how wonderful and amazing these vehicles really are.

M151 Jeep, Willys Jeep

Half - Track Personnel Carrier

EVT-100 Armored Car

M-114 Armored Fighting Vehicle

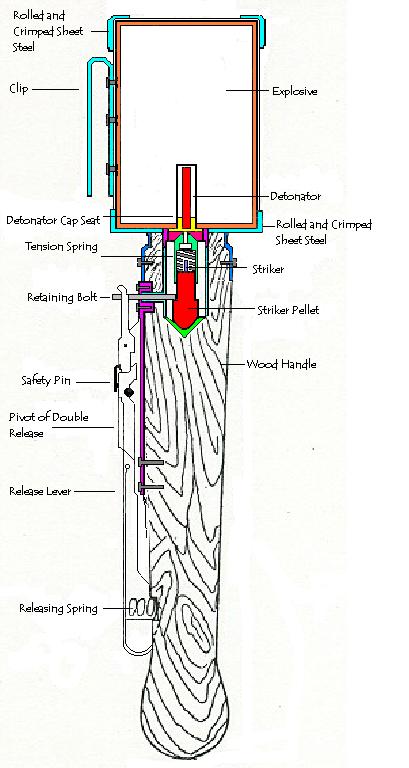

THE PINE APPLE

As America settled down about its business of World War I, it found itself devoid of an effective item for the form of warefare then taking place. It was obvious that borrowing an item of such intrinsic value as a Hand Grenade from the French (F-1 Grenade) and/or English (Mills Bomb No 36 Mk1) for the duration of the conflict was out of the question. In reality, neither country could sustain the production requirements of a protracted conflict. Thus, the impetus for development of the American Hand Grenade was true need.

In a report entitled, "America's Munitions" by Benedict Crowell, Director of Munitions and Assistant Secretary, published in 1919, we discover that by August 20, 1917, the Trench Warfare Section had developed the design and the drawings for the defensive grenade. The first contract for 5,000 grenades was let to the Caskey-Dupree Company of Marietta, Ohio. This award, a mere drop in the bucket of the total needs of the war effort, was given as a result of the design and development which had taken place almost entirely at its plant in Marietta. Elsewhere, more contracts were being let with factories tooling up for the anticipated production of 21,000,000 of what was to become adopted as the MK I defensive grenade.

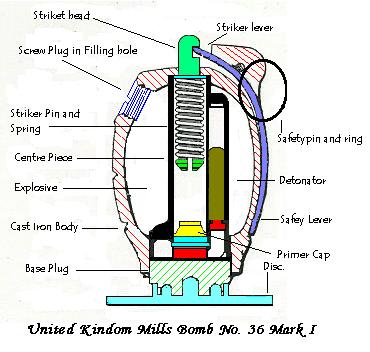

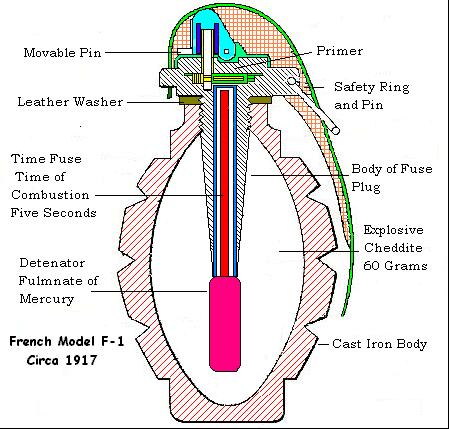

In development of the United States item, the fuzing systems of Allied and Axis grenades were examined. The French fuzing systems impressed the design bureau of America as unduly complicated employing small parts that may well attract corrosion or malfunction due to the harsh environments of trench warfare. The French used this common fuzing system on both their defensive (Fragmentation) and offensive (concussion) grenades. The English system, while sealed seemed also not of the mind set as best fitting of the overall conditions and was feared as not having a 'positive' enough safety lever. In addition, the explosive design where the detonator was located to one side was not viewed as a positive method of transferring the shock wave depending on sympathetic detonation.

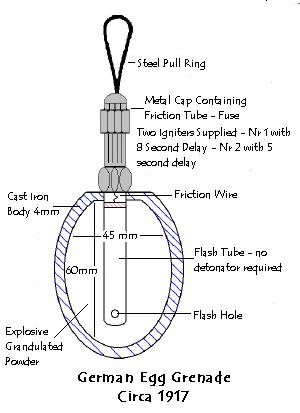

What did prove to be attune to the American designers was the serrated body of the device. Other fuzing systems did exist which proved both functional and reliable in the prevailing conditions of the day. Of these was the pull fiction fuzing of the German grenades. Essentially these employed a sparking material against a harsh surface producing ignition and thus the delay train of the grenade. As in the American, English and French, the German solution would carry forth its basic design into the World War II era. The German 'Pull Friction' fuzing system was also used in what came to be known as the 'Egg' grenade. This device simply adopted a 'mini' grenade approach to trench warefare.

The U.S Model MK I outwardly resembled the item as we know it to exist today. The body was fabricated from malleable iron and scored into 40 sections with a threaded base-loading plug. The main charge consisted of four ounces of flaked or powdered TNT, a Bouchon fuze system, delay train with C6 blasting cap. This fuze system would be type excepted and called the MK V (M5). In the manual, Hand Bombers of 1918, the fuze delay time was stated as, "...it burns for 5 seconds plus or minus 3/5 second." The MK l body was black in color being coated in a non-acid paint.

'The one item that separated this from the later versions was that after removing the split pin, the thrower must turn the safety handle to allow the striker to be set free and start the delay train. From the onset, this system was doomed with problems. In the manual of Hand Bombers and Rifle Grenadiers produced by the War Plans Division in July of 1918, the conditions surrounding the MK I operating system was described. In this, it said, ... the lever mechanism of the American Hand Grenade (Mark I) was considered too safe and caused many malfunctions. In some cases where 40 student officers took part in throwing a live barrage from the trench, it was found that at least 30% of the grenades were not armed when they left the trench. From Benedict Crowell's American Munitions of 1919, another story is recanted. In this it says, "... the well-known story of the soldier who... threw his grenade to soon because he could fell it "swelling" in his hand applies to most soldiers in battle. In using the new grenade, the American soldier would not go through the operations required to fire its fuse." The new grenade was referred to was the MKII.

On May 9, 1918 a cablegram was received in Washington from the American Expeditionary Forces that brought the entire effort of manufacturing the MK l to an abrupt halt. In no uncertain terms, the American commanders had condemned the MK I and it would be used no more.

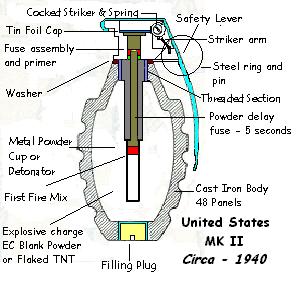

By August 1, 1918, the new American grenade called the MK II was developed and placed into production. The same configuration was incorporated as was the main bursting charge of TNT or Trojan grenade powder. It also retained the base loading plug, however, the body was now painted gray and the safety lever was a bit shorter then the versions and, of course, was of the "Mills" or swing off variety. Through out the remainder of World War I, this was the item most found in the hands of American soldiers.

The MK I as well as the MK II both had practice versions that consisted of the body devoid of explosive filler and the bursting charge filler plug. As a special note of concern to the trainer the device came complete with the caveat that the M5 fuze may "break open the body and cause injury." One interesting note is the Grenade Training Manual of January, 1918 which states, "if no practice grenades are furnished by the Ordnance Department... arrangements might be made with a local foundry to construct bodies ... as per specifications. One of the first corporations to make such was the Alamo Iron Works, San Antonio, Texas, who charged 10 cents for making a body of this type.

In reviewing the above, one item comes immediately to light. What of the periods in which the U.S.german~1.jpg (20938 bytes) was engaged in conflict prior to the start up of manufacture of the MK I? The French F1 and English No 36 were in short supply with their commitment of first supply to their troops. The answer is found in the popular doctrine manuals of the day. In short, it was the belief each 'special' solider should be trained to make improvised explosive devices.

In the pamphlet entitled Grenade Training Manual prepared at the infantry School of Arms, Ft. Still, Oklahoma in January 1918, we see a bit of how the general thought process was engaged. In this manual it says "... at the beginning of the war, allies were forced to construct and use improvised, but now the different combatant powers have more then an ample supply... however, owing to the lack of adequate equipment, the American bomber should know how to construct satisfactory types ... besides, it will serve as a means of instruction in handling explosives, fuses, and detonator, and this is the big lesson which only live practice teaches."

The Grenade Training Manual of 1918, depicts two primary types of improvised grenades as preferred. Firstly the "jam tin." In this item what is described as an ordinary "jam tin" (about the size of a Sardine can) filled with ... scrap metal leaving room for half pound of dynamite, TNT, or gunpowder, however, in the latter, it is necessary to give through tamping. Secondly, the "hair brush" so derived as from its peculiar shape. This item consisted of a piece of wood about 20" long with a stick of dynamite or a "block of TNT with Bickford fuse and lighter."

To fully develop the MK II into what most of us know today, another step was necessary. In the Basic Field Manual, Volume III, Chapter 5, Instruction With Hand and Rifle Grenades, 1932, a new grenade was described In this item the body remained the same with 40 deep serration's (48 counting the fuze neck), a filler plug with the body painted yellow and the main bursting charge consisting of .74 ounce of E.C. blank fire smokeless powder. The designation of E.C. indicated the proprietary compound first made by The Explosive Company seen in blank rifle cartridges. The fuse was changed into what became known and type expected as the MK X (M 10 later shown on the fuze), and had no blasting cap assembly. In this particuar series the ignition came by way of a small black powder ignition pellet.

During the era between the wars, both versions of the MK II were being manufactured. That is to say fillers of TNT with the M 5 fuze, and the "new" MK II with the E.C. powder and the M 10 fuze. Each of these items were given a bit more identification and described in the Basic Field Manual, Hand Grenades, FM 23-30, of 1940. Both grenades were painted yellow, however, one item was unique to the pair. In the TNT versions, the fuze was shipped separately. This unique feature was the case in all TNT based grenades to include the MK I. In each of the TNT grenades a small wooden plug was fitted into the body and thus must first be removed and the items "fuzed up" for use. These facts as well as the notation of the continued use of the M5 in the practice version of the MK II was also seen in Technical Regulations, No. 1350-B, published by the War Department, May 16, 1939.

With ever growing concern of student injury from using the M 5 fuze system in a training grenade the decision was made for a redesign. While the concern was great, it certainly wasn't enough to suggest manufacturing a new device until existing stocks were depleted. The Field Training Manual for Grenades for the Infantry Arms School at Ft. Sill of 1941, illustrates the Fuze M10A1. This fuzing system was the first made specifically for instruction. The grenade itself consisted of a blue body with a cork in the filler plug area. The detonator assembly contained a black powder charge " that it should provide a loud report." Other publications of this period also indicated that the M10A1 fuze was also used on the exploding version where E.C. powder was the bursting agent. It seems they just couldn't get away from using flaked TNT or loose powder. In both of these approaches the concern of detonation was obviously not a factor.

As our country crept ever closer to entry into World War II, the need was seen for enhancement of this all-important instrument of harm. In contract number W-672-ORD-3446 let in April, 1941 a here-to-fore serious flaw of American thinking was corrected. The Antonelli Fireworks Co, Inc., an accomplished manufacturing concern, received the contract where MK II's were refitted with the M 41 container. While this may seem of small significance, the new container gave enhanced protection while being shipped, and in addition the new M10A2 fuze was now available.

In 1942 the MK II, grenade as we most often hold the vision came into being. The design was changed omitting the filler plug at the bottom, and the body color became O.D. (shade 24087) with a yellow band at the collar. The 'yellow band' was a common identifier of the device having a TNT base charge. Another significant improvement was a new fuze giving off less smoke and being non-sparking was type accepted and introduced as the M10A3. The basic fuzing system developed for the MKII also served (with item specific variations) in all series of American grenades with the exception of one variety with uses an electronic system.

Using the basic application of a standard type fuzing system, the United States developed an entire series of grenades, many of which were cataloged as special purpose. Above are illustrated examples of these items. In the Phosphorus grenade the hot burning substance was actually classified as a 'smoke' grenade for signaling. While the item was seldom employed in such a role, it was soon to be come a popular item in combat. To attack an enclosed target the Offensive Grenade was developed. Having a case of fiberboard impregnated with tar the main bursting charge was cast TNT. The obvious uses were to 'over pressure' a target where the concussion of explosion would defeat an enemy. Also developed was a series of smoke grenades that were designed to expend various colors of smoke to perform screening and signaling. Emitting a dense white smoke the screening device was known as HC. Signaling smoke grenades came in such colors as yellow, green, violet and red. Also developed were Tear Gas grenades of both varieties of lacrimates (CN and CS). Also included in the CN & CS version was a vomiting agent known as DM.

A unique series of hand grenade developed for the US was the illuminating grenade. Consisting of a 'Quick Match' fuzing assembly, a chemical delay ignited a 'flare' thus illuminating an area chosen by the projecting soldier.

This was not the end for the good ole Mark Duce, However, it served well into the Korea era fitted with again another family of fuzes known as the M204, A1, A2, and A3. Almost as if it had a life of it's own, the MKII continued in production by several countries. Of the countries producing the ole MKII was Chile. Produced for many years, this grenade and it's refined fuzing system would provide the basis for a number of high quality items made at the Industrias Cardoen SA in Santiago.

Grenade development continued in the United States where in the 50's a version that became known as the M26 series was manufactured. This grenade consisted of a thin sheet metal body with a internal spiral spring or fragmentation coil. The device used a main bursting charge of Composition B that has general characteristics of TNT. This particular series was unique past its departure from the 'pineapple' body. It was felt the design of this new series would correct the circumstance where the MkII would not uniformly dispense fragmentation. The MkII had a propensity to split into large chucks giving an uneven injury pattern. The M26 was a substantial improvement but remained lacking in a perfect pattern response. An additional uniqueness was the fitting of an electronic impact fuze system. The theory attached to this innovation was to prevent the item from rolling back upon the person projecting it when employed against a target on an incline.

The M26 series used through the Viet Nam era was also supplemented with what now is the standard issue for United States forces. The M59 series or 'baseball' grenade was introduced further addressing the concern of uniform fragmentation. This series particularly spoke to the situation where the grenade would land on it's side and has come closest to consistency in potential.

The future of grenade development now lends into the plastic age. Internationally some companies produce grenades that almost total plastic. With the advances of ceramics event the fragmentation sections are changed to reflect the technology of the day.